Information

Joint development of energy-saving rudder ~Recovering the rotation loss of the propeller, Reducing GHG ~

TOKYO-Mitsui O.S.K. Lines, Ltd. (MOL; President & CEO: Junichiro Ikeda) today announced that, a group company MOL Techno-Trade Co., Ltd. (MOLTech; President: Hirokazu Hata), MOL, Japan Hamworthy Co., Ltd. (JHC; President: Kazushi Tomita) and Akishima Laboratories(Mitsui Zosen) Inc. (Akiken; President: Taiji Maeda)are conducting research and development on the propeller-mounted energy-saving device called PBCF (Note 1) and the energy-saving rudder with bulb fins. We confirmed the energy saving effect of more than 5% with only the energy-saving rudder with bulb fins.

In the development of energy-saving rudder with bulb fins (hereinafter the “developed rudder”), we have enhanced the energy-saving performance and improved horsepower by taking advantage of the steering effect of the rudder of JHC, a specialized manufacturer of high lift rudder such as schilling rudder. The features of the developed rudder are as follows.

1) In order to recover the swirling flow of the propeller, the reaction shape is designed as a high thrust blade section and the rudder horn is also twisted and integrated so as to increase thrust due to the negative pressure on the rudder.

2) By reducing the size of the end plate under the rudder, the resistance is reduced and the propeller swirl flow is also blocked.

3) The large central bulb has a flat front surface to reduce the propeller inflow speed and improve propeller efficiency.

We used JBC (Japan Bulk Carrier) hull, which is open to the public as a general large-sized hull and widely used in various research and development. Generally, it is difficult to improve the horsepower by 4% or more with a normal reaction rudder. However, with the developed rudder, CFD (Computational Fluid Dynamics) showed 5.7% improvement in horsepower and a self-propulsion test in a large towing tank confirmed 5.2% improvement.

The developed rudder has been applied to the slender ship types as well, and an energy-saving effect of 4.4% has been confirmed by CFD. In the future, we plan to conduct a large towing tank test after performing optimization work.

We will continue to improve the efficiency by aiming for a synergistic effect with the torque reduction effect of PBCF for the future installation on actual ships. The developed rudder has been patented.

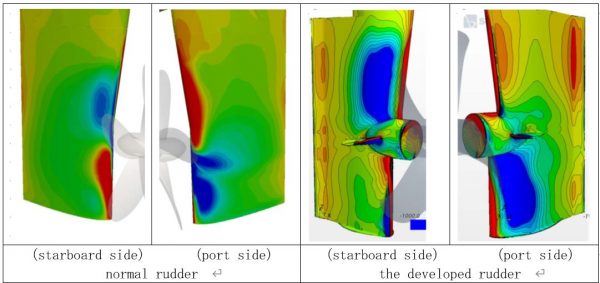

Pressure distribution of starboard side and port side by CFD (blue indicates negative pressure, red indicates positive pressure)

The pressure change (red to blue) on the rudder surface is caused by the rotation of the propeller. In other words, it flows in from the port side at the upper rudder and from the starboard side at the lower rudder. We aim to develop a rudder that effectively recovers the energy loss of the swirling flow induced by a propeller.

(Note 1); PBCF: Propeller Boss Cap Fins. A device attached to the propeller of a vessel. It breaks up the hub vortex generated behind the rotating propeller (resulting in energy savings of 3% to 5% compared to an identical vessel not equipped with PBCF).

Contact: r.d.promotion@motech.co.jp

R&D Promotion Office, MOL Techno-Trade Co., Ltd.